EVT’s NANO for cleaning small and very small parts in small batches is probably the most attractively-priced solvent degreasing plant available in the European market today. Even better, it offers mature process technology and a host of options for turning your NANO into “the right plant for your specific needs”.

High plant uptime is ensured by our online remote maintenance and diagnostics service, which we developed in collaboration with SIEMENS. From an iPhone or iPad, we can query data and change settings anywhere in the world to quickly and efficiently resolve both apparent and real malfunctions and problems.

This ability to remotely access and service your plant, together with complete turnkey manufacture of plants in compliance with our own rigorous standards of quality at our factory in Sternenfels, Germany, enables us to offer a three-year warranty on every EVT plant supplied!

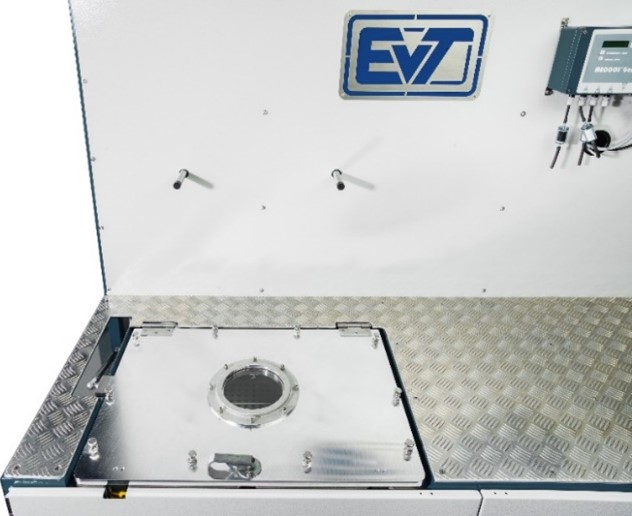

The standard version of the Nano permits vapour degreasing, immersion and drying. It can be delivered with various options that include ultrasonics, a rotating device and vacuum drying, or else prepared for these options to be retrofitted at a later time.

You can get the Nano ready for operation yourself without any assistance from our service personnel: simply install it at a suitable location, connect it to the power mains and a source of compressed air, fill it with solvent – and you are set to go.

The plant can be delivered with an activated charcoal drum or with a regenerable activated charcoal filtration unit.

TECHNICAL FEATURES

| Usable solvents : | Perchloroethylene (PER), Trichloroethylene (TRI), Brominated Hydrocarbons (nPB) |

| Solvent content : | ab 120 dm³ |

| Weight of the plant : | 600 kg |

| Throughput : | 2 – 3 charges/h, 50 kg/h |

| Basket dimensions : | 320 x 220 x 200 mm, (Schäfer B) |

| External dimensions : | 1750 x 1200 x 1000 mm, 1750 x 1200 x 1700 mm |

| Operating mode : | 1 – 3 shifts |

PUT US TO THE TEST

We can try our solutions to your surface finishing and cleaning problems together. We will evaluate the results and make suggestions about your problems on surface finishing and cleaning processes.

Send us some sample, we will transmit you the results and our suggestions in the form of a process report.