Thermal deburring (TEM - Thermal Energy Method) is a process for removing production-related burrs from various machined parts which are caused by milling, drilling, etc. The scientifically correct name for TEM is “thermal-chemical deburring process”. It is assigned to the DIN 8590 subcategory of abrasive methods “chemical removal”.

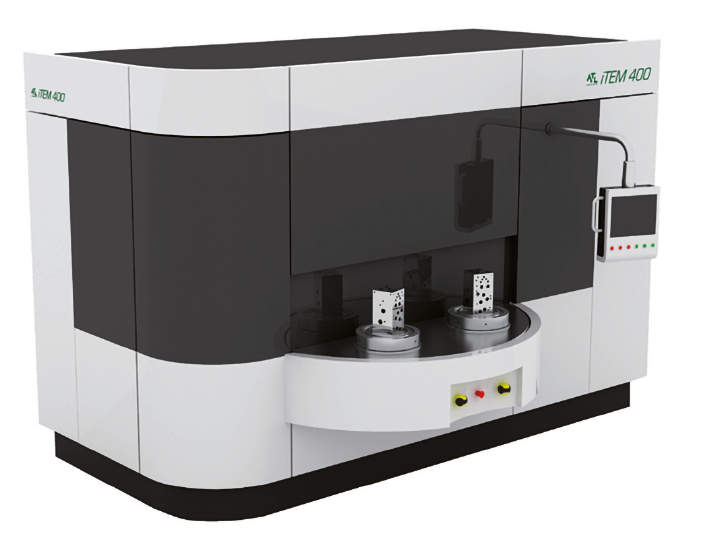

The material to be removed is burned due to a chemical reaction between the material and the gas mixture. For this purpose, the workpieces are placed in a bell-shaped deburring chamber which is hydraulically closed by a closing plate. An accurately defined mixture of gases is fed into the deburring chamber via a gas metering system and ignited by a spark. The temperature of the subsequent combustion ranges from 2,500 to 3,300 °C (4,532 to 5,972 °F).

With this combination, the burr reaches its ignition temperature and reacts with the excess oxygen inside the deburring chamber. This leads to a complete combustion of the burr within 20 ms. Various metallic materials as well as all thermoplastics like PA, PE, PUR, and PMMA, but also injection molded parts without glass fiber content can be processed. All in all, the cycle time of the thermal deburring process is less than two minutes.