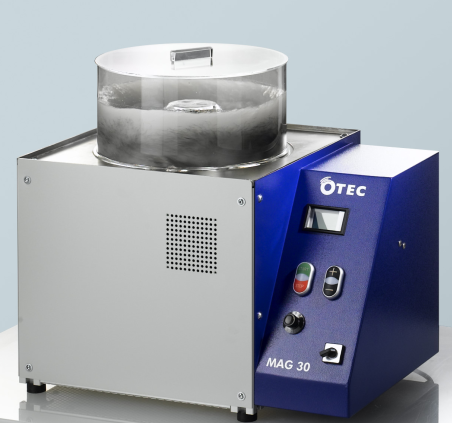

Disc finishing machines have been used for many years on deburring and polishing of small and delicate materials with high quality and sensivity. Processing is carried out in an open drum (the process container) with a base plate in the form of of turntable or disc. The workpieces, together with a suitable polishing or grinding granulate, are set in motion by the rotation of the disc to create a toroidal stream inside the stationary drum. The contact between the workpieces and the medium generates a very intense finishing effect which is up to 20 times more efficient than can be achieved with systems such as conventional vibrators. The most important point in disc finishing machines is the gap between the disc and upper cylinder. The gap is under a high pressure during the process which creates a high wearing effect. So the gap must be very stable and strong against wearing to avoid gap getting bigger and also must be suitable to be adjusted as small as possible tool at the customer process fine parts and use fine media. Thanks to Otec special ceramic based gap design, we can adjust our wet procesing containers with 0,40 mm , dry processing containers 0,05 mm gap which is the smallest can be achived in the market and Otec’s unique zero-gap system make it possible to process thinner workpieces lower than 0,40 mm with smaller medias.

Devamı