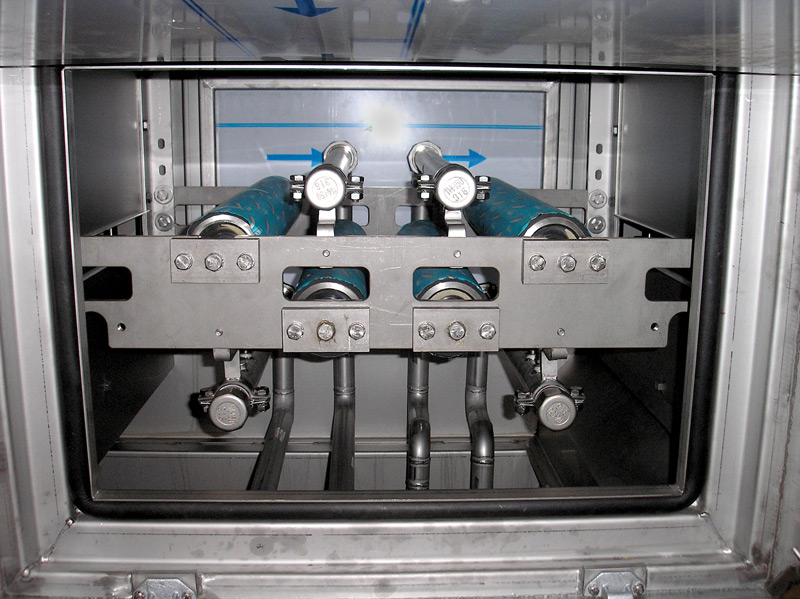

YukonDA is a spray cleaning system for continuous material flow which is adapted to cus- tomer requirements. The parts pass through the successive treatment zones continuously (synchronised if required). Cleaning is carried out by passing the parts past the fixed nozzle systems.

APPLICATIONS

TECHNICAL FEATURES

Basic system

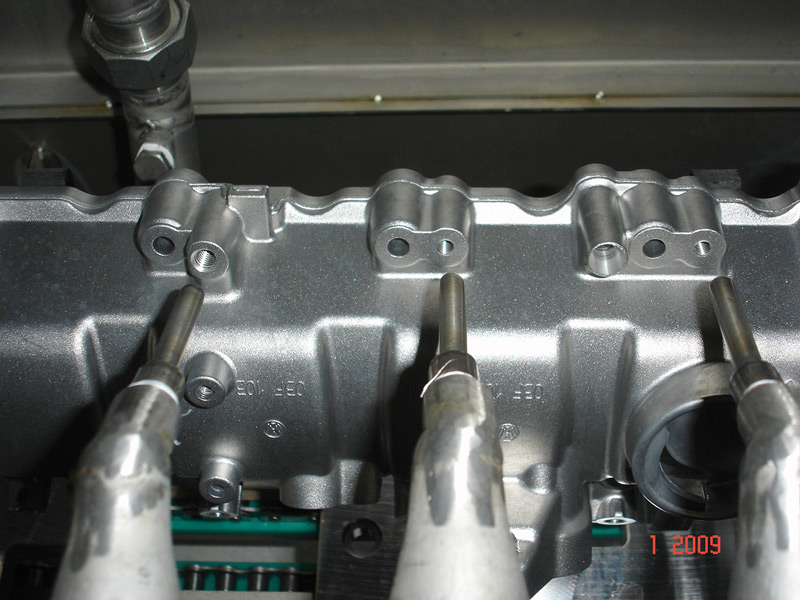

| Cleaning system | spray cleaning with flat spray nozzles |

| Rotation | flow-through process |

| Number of tanks | 1– x |

| Loading | from the front, individual loading of the charging station |

| Housing | stainless steel |

| Tank insulation | stainless steel |

| Control and operation | Siemens Simatic with operating panel |

| Bath monitoring | Libelle Fluid Control |

Measuring bath contamination

New standard feature!

On the occasion of our 25th anniversary, BvL are equipping all systems with the bath contamination monitoring system Libelle Fluid Control as a standard.

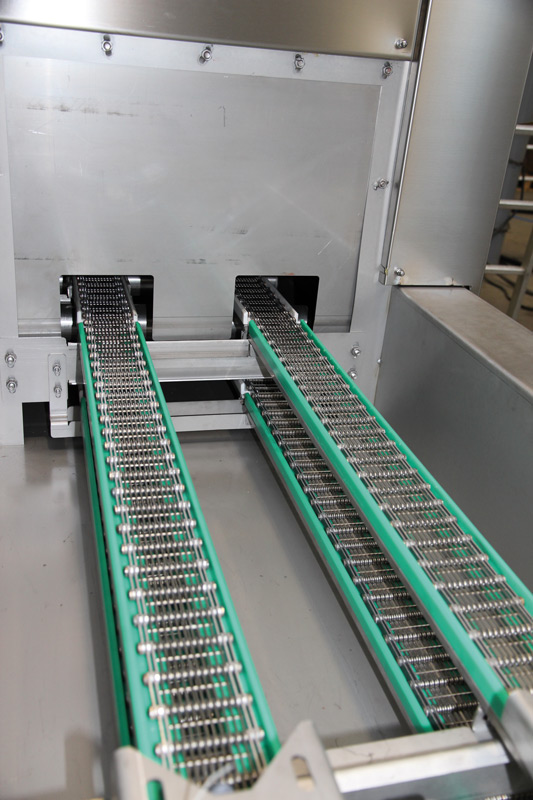

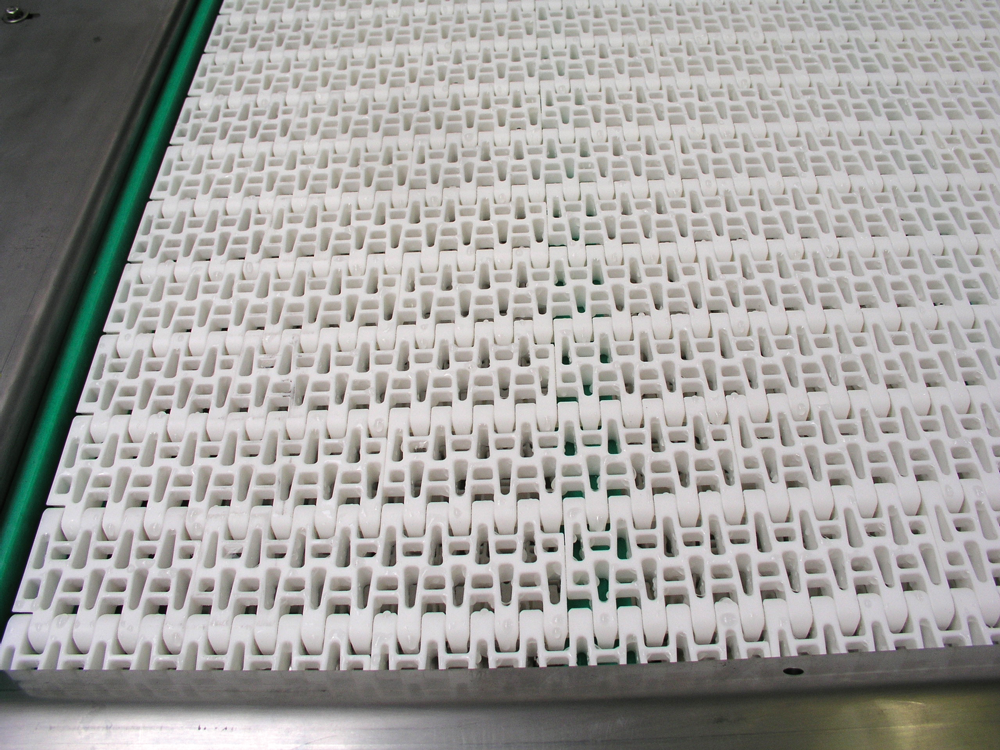

Versions and conveyor systems

The right system for any requirement: BvL conveyor systems adapt perfectly to your produc- tion process. We have the right conveyor system for your component, depending on size, geometry and weight. The nozzle systems are also customised to suit your workpieces, ensu- ring thorough cleaning even in hard-to-reach places.

| System examples | Unit | Ex. 1 | Ex. 2 |

| Usable width | mm | 250 | 2,000 |

| Usable height | mm | 100 | 800 |

| Loading capacity | kg | 20 | 400 |

| Tank volume 1 | l | 950 | 5,000 |

| Tank volume 2 | l | - | 3,000 |

| Tank volume 3 | l | - | 3,000 |

| Tank volume 4 | l | - | 5,000 |

| Tank volume 5 | l | - | 3,000 |

| Total length | mm | 2,400 | 29,500 |

PUT US TO THE TEST

We can try our solutions to your surface finishing and cleaning problems together. We will evaluate the results and make suggestions about your problems on surface finishing and cleaning processes.

Send us some sample, we will transmit you the results and our suggestions in the form of a process report.