OtecCF Element machines stands for high performance and ease of use. Its top-quality steel frame makes the CF Element very stable and quiet in operation.

Outstanding value for Money

This machine is based on the reliable and proven technology of the CF series. The CF Element series with its robust process drum, is therefore very reliable and extremely cost effective.

For wet and dry applications

The CF Element version is available for both wet and dry finishing of workpieces as well as zero gap system for special needs.

Clear display

Detailed information on the processing cycle, elapsed time and speed is shown on the display panel.

APPLICATIONS

TECHNICAL FEATURES

Disc finishing machines in the CF Element series are suitable for all applications which call for a cost-effective and perfect surface finish on workpieces which vary in shape and size. The difference between the centrifugal forces acting on the workpieces and the process medium creates a very powerful finishing effect. This can be up to 20 times more efficient than, for example, conventional vibrators.

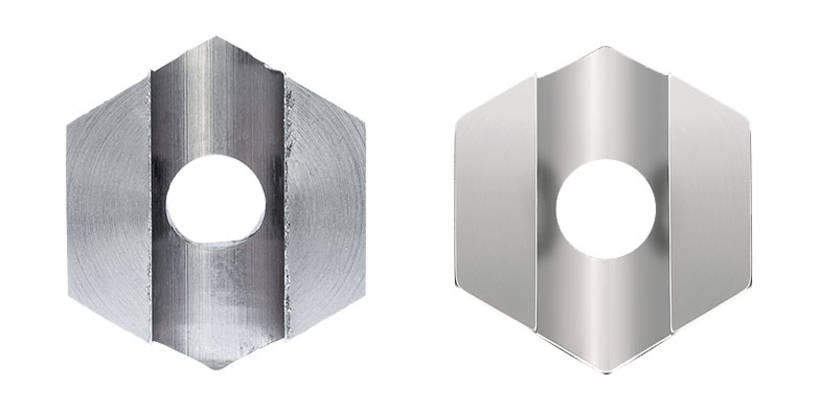

CERAMIC GAP SYSTEM

With this system, the gap can be set to an accuracy of 0.05 mm since it is formed by using two ceramic rings made of SIC. this technology is best suited to dry finishing since it enables best results to be obtained by using very fine polishing granulates.

CERAMIC/POLYURETHANE GAP SYSTEM

This standard system from OTEC is suitable for the most common applications in wet finishing. The cermic/polyurethan combination prevents any workpieces from becoming lodged in the gap area, making the process very reliable and reducing maintenance requirements.

UNIQUE ZERO GAP SYSTEM

For the wet finishing of very fine workpieces. The gap between the rotating disc and the stationary drum can be reduced to zero. This enables very fine grain abrasive media such as quartz to be used and prevents any workpieces from becoming lodged in the gap.

PUT US TO THE TEST

We can try our solutions to your surface finishing and cleaning problems together. We will evaluate the results and make suggestions about your problems on surface finishing and cleaning processes.

Send us some sample, we will transmit you the results and our suggestions in the form of a process report.