Advantages and application fields.

- Compact and space saving.

- For small parts in baskets or individual parts on workpiece holders.

- For parts with recesses or cavities.

- For light to medium soiling.

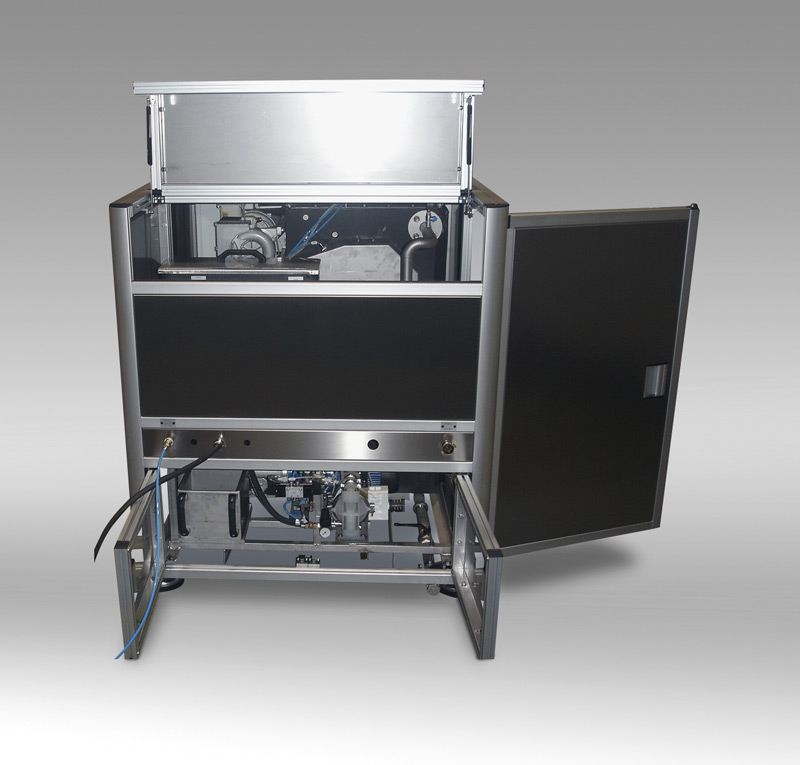

Niagara EM is a compact flood spray cleaning system with revolving wheel technology. The sys- tem features a modern and compact design. All processing steps are carried out in a chamber. Rotating the baskets or workpiece holders around the horizontal axis ensures all-round thorough cleaning.

TECHNICAL FEATURES

| Cleaning system: | spray cleaning with flat spray nozzles |

| Rotation: | revolving wheel system with fixed nozzle frame |

| Number of tanks: | 1 |

| Loading: | front loading through a roller guided holding fixture |

| Housing: | compact stainless steel housing |

| Tank insulation: | yes |

| Control and operation: | Siemens Simatic with Siemens touch panel |

| Bath monitoring: | Libelle Fluid Control |

Measuring bath contamination

New standard feature!

On the occasion of our 25th anniversary, BvL are equipping all systems with the bath contamination monitoring system Libelle Fluid Control as a standard.

| Standard sizes | Unit | 480 | 600 |

| Usable length | mm | 480 | 600 |

| Usable width | mm | 320 | 400 |

| Usable height | mm | 200 | 300 |

| Loading capacity | kg | 50 | 100 |

| 1 tank system: volume | 280 | 350 |

PUT US TO THE TEST

We can try our solutions to your surface finishing and cleaning problems together. We will evaluate the results and make suggestions about your problems on surface finishing and cleaning processes.

Send us some sample, we will transmit you the results and our suggestions in the form of a process report.