Components used in the aerospace industry must be made to withstand extreme environmental conditions. In modern gas and aircraft turbines, for example, combustion temperatures of well over 1,000°C are common. This places very stringent requirements on the surfaces and materials used, as well as on the manufacturing and finishing processes.

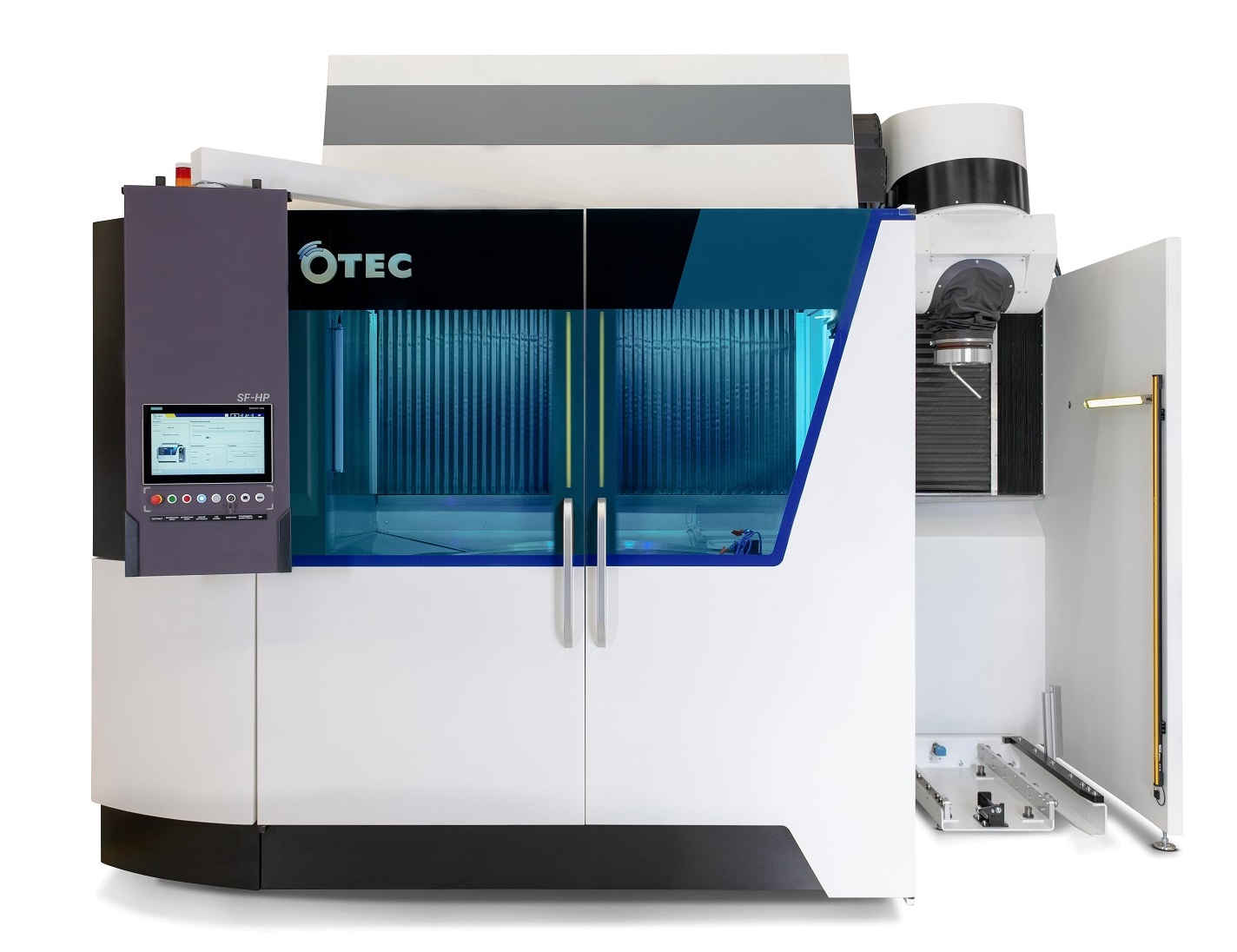

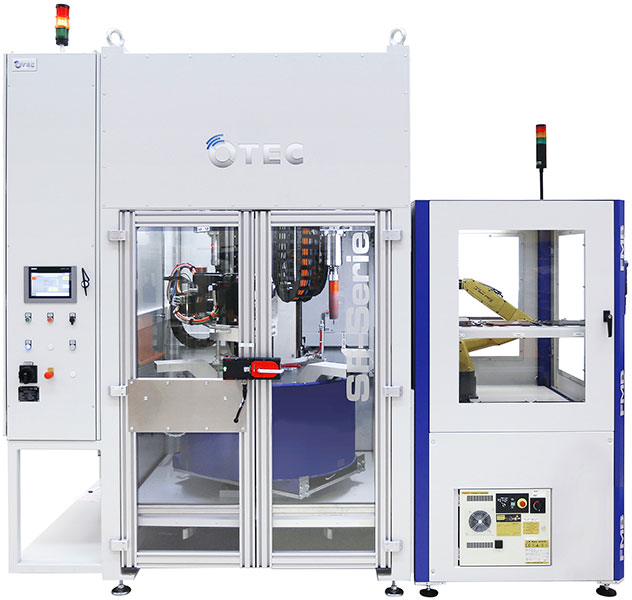

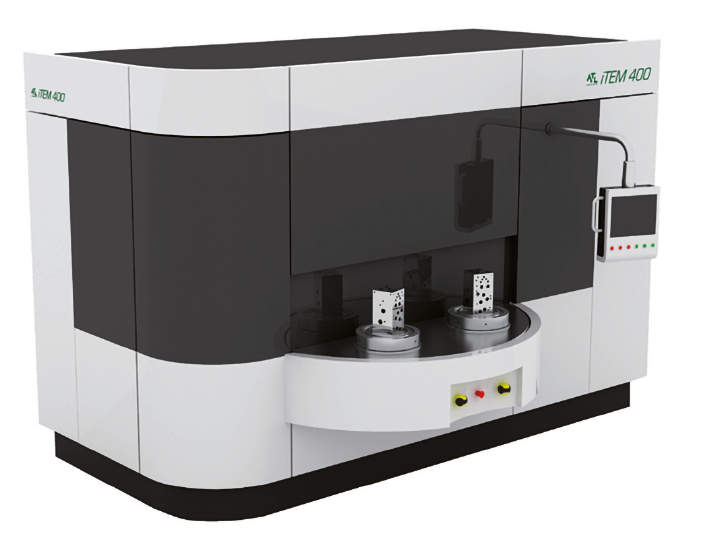

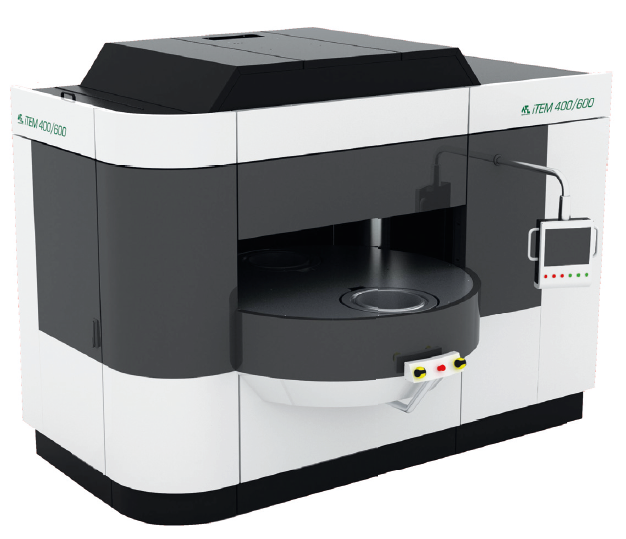

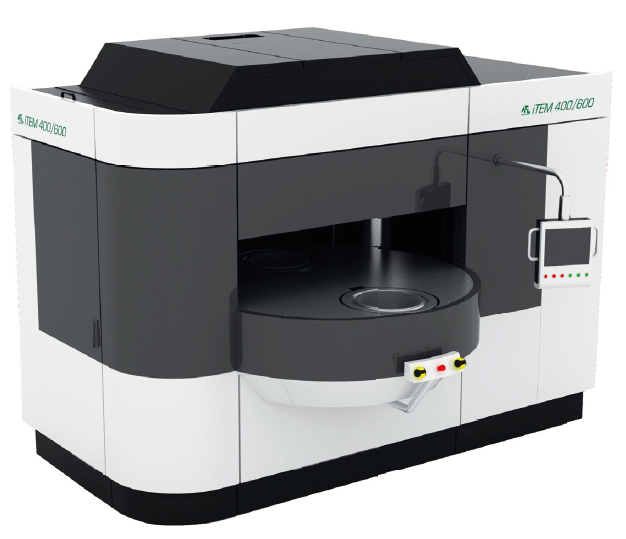

Complex components for the aerospace industry are often finished manually. The disadvantages of this are not only the high costs but above all, the fluctuations in the results of the finishing processes. With OTEC machines, reproducible results can be achieved with the best surface quality in the shortest possible processing times.

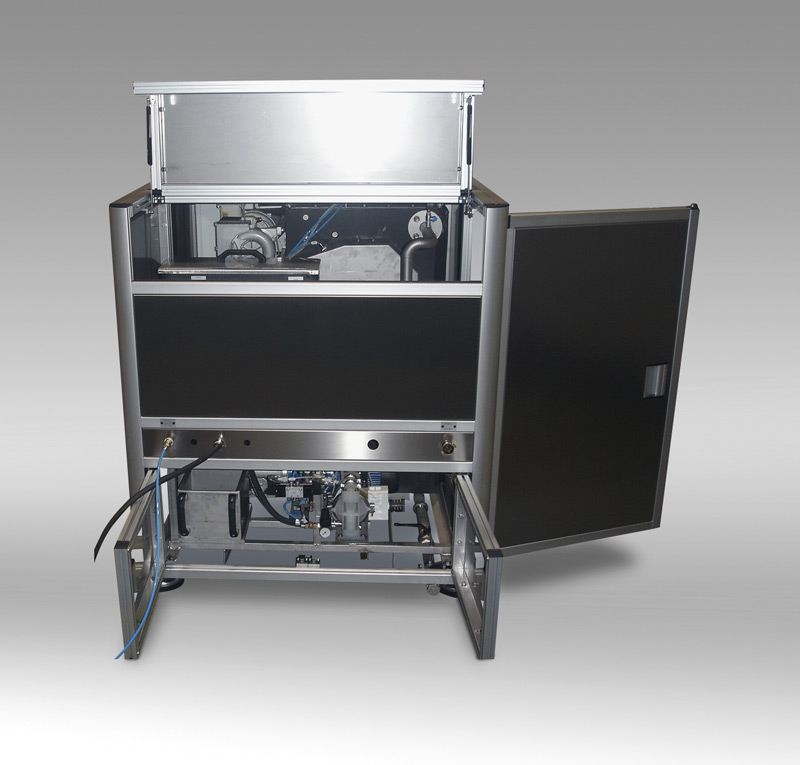

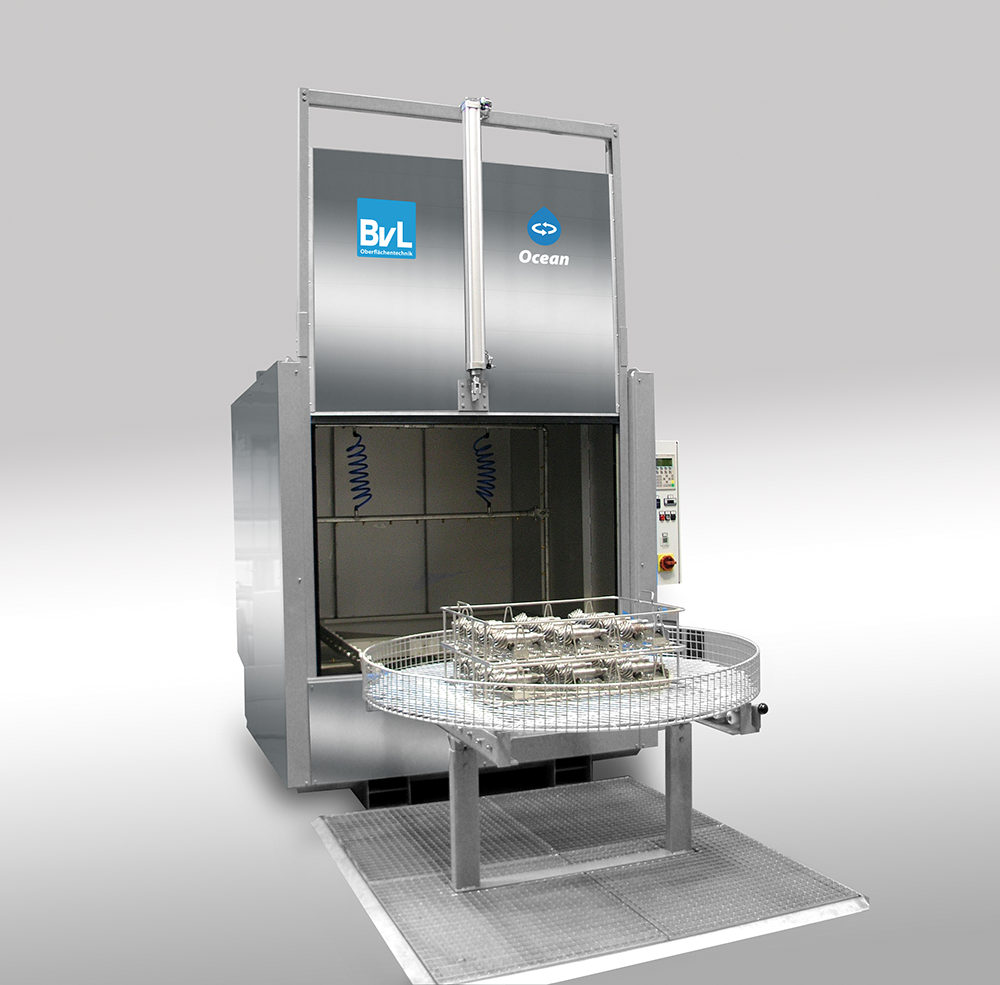

Perfection and quality are the measure of all things not only for Elma, but also in the aerospace industry. In order to meet these high standards, Elma provide quality not only for the development and manufacturing of equipment and systems, but also and particularly for service and customer care.

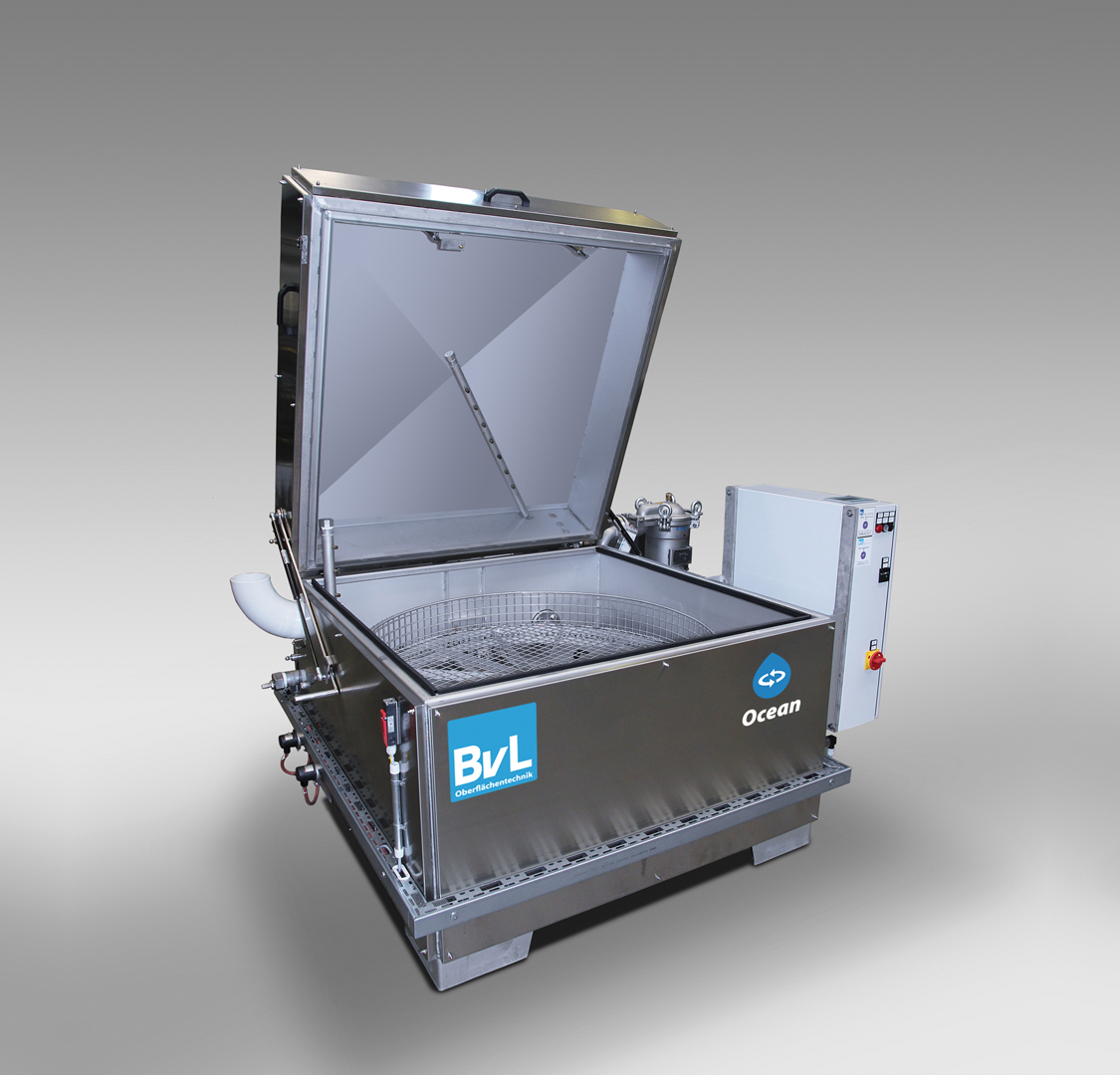

Different validatable equipment and systems are available for every cleaning stage for the cleaning of components in the aerospace industry. Whether it is for reconditioning cleaning, NDT/FEP tests, pre-, intermediate or final cleaning, Elma provides tailored cleaning solutions.

Turbine Blades: After they have been manufactured, turbine blades must be subjected to surface finishing before they can be used in an aircraft or for generating electricity, since the initial roughness value is too great or the edges are too sharp. This entails both smoothing the surface and rounding the edges. In OTEC machines, the surface is homogeneously smoothed, generally to Ra < 0.4 μm and often to less than Ra 0.25 μm. Here, it is especially important to ensure that the shape of the blade is not damaged. Furthermore, the inlet and outlet edges must be rounded to a predefined dimension. The process times are between 2 and 30 minutes. Several workpieces can be clamped in the machine at the same time, which gives a very high throughput.

Gear Wheels: With gear wheels, it is often a matter of smoothing the tooth flanks or rounding the tooth tip. Finished gear wheels have considerably lower friction values.

Gear wheels finished in OTEC machines have a lower Rpk value and therefore lower friction, which in turn increases energy efficiency. In addition, oil change intervals are longer because less metal abrasion is deposited in the oil.